Auto Duct Line

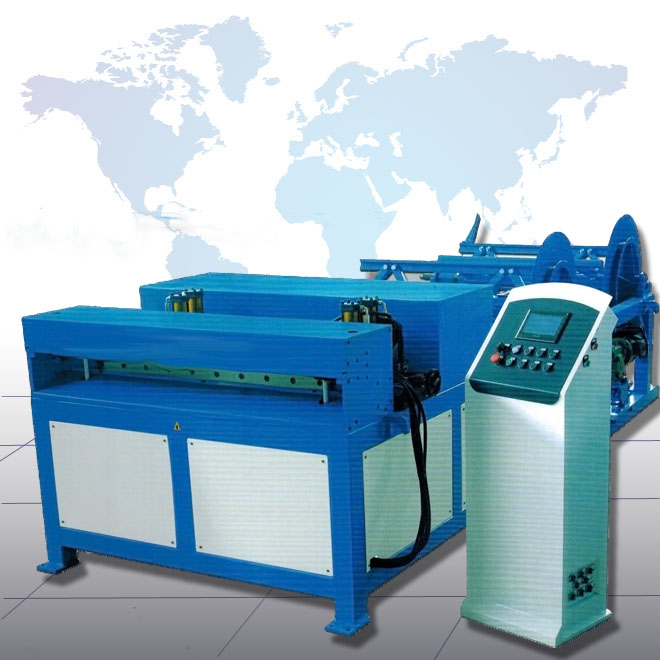

Duct Manufacturing Auto Line II

- Model No.: SDJL-II

- Product Size: 4800*2460*1450

- Net Weight: 4400

- Product Power: 10KW

- Product Material: Galvanized sheet

Line II consists of a metal frame, leveling and beading machine, punch and punch square oil press, hydraulic shears.

The control part adopts automatic computer control, the control system is a closed-loop feedback system, the production of precision and stability are obviously improved. The maximum operation speed is 16m/min. Length error of +-0.5mm, +-0.8mm, diagonal error.

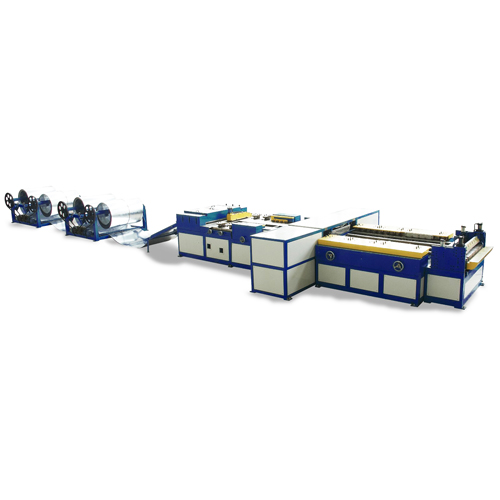

Line II can meet the wind tube sheet material, mainly TDF (flange) material, Synthesis of the wind pipe production line and flange machine, bite machine, plate folding machine, plus the corner will be able to produce high quality standard corresponding wind pipe.

Basic equipments

1. Electric feeding rack 1pc (2620*1850*1450mm)

2. Leveling grooving device group

3. Hydraulic angle cutting machine four sets including moulds

4. Hydraulic shearing machine

5. Computer and controller with a set of software production

Features

1. Sizing material can be directly with the computer with the use of plasma cutting ingenuity.

2. a. C or S plug-in bone shear angle can be used with the C bone and S bone reel machines.

b. Various TDF flange connection method to locate the shear angle, and TDF flange machine, folding machine with the used of TDF.

Specifications

| Model | Plate thickness (mm) | Plate width (mm) | Max-working speed (m/min) | Coiler weight (kg) | Weight (kg) | Dimension (mm) |

| SDJL-II | 0.5-1.2 | 1300 | 16 | 6000x2 | 2400 | 4800x2160x1450 |

| 1600 | 2600 | 4800x2460x1450 |

Note: customers can order the line with different sheet specifications, sheet width and coiler weight.

CATEGORIES

LATEST NEWS

CONTACT US

QQ: 2682507192

Phone: 18133429808

Tel: 0555-5207358

Email: oliver.he@tenroy.com

Add: Yanyang road, Huashan district, Maanshan city, Anhui province, China