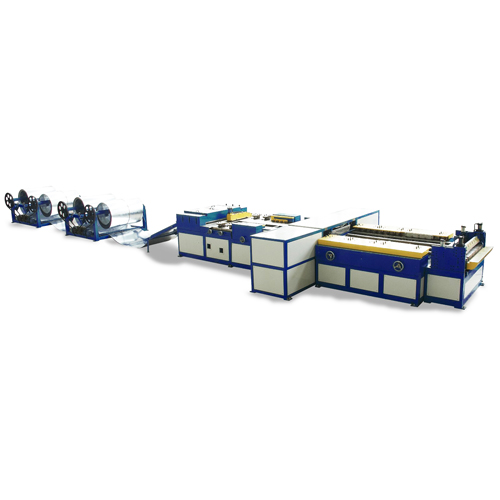

Auto Duct Line

Auto Duct Line V

- Model No.: SDJL-V

- Product Size: 18000*3800*1300MM

- Net Weight: 10000

- Product Power: 28KW

- Product Material: Galvanized sheet

Duct production line V is composed of feeding rack, leveling embossing, hydraulic punch sharp opening and square opening, hydraulic shearing machine, displacement type joint angle lock forming machine, manipulator grabbing assumed feeding plate form, double linked total plate flange machine and dual linked single bone forming machine, servo feeding plate form and TDF hydraulic folding machine. The electrical control part adopts full computer control, bending servo feeding, positioning precision. Especially when process “口” shape opening pipeline, it can ensure the bending precision. The max feeding speed is 16m/min and the length tolerance is +-0.5mm. You can choose this production line to process TDF total plate flange and angle steel flange ventilating duct. The exchange is simple and rapid.

Features

1. This auto line V covers small area with linear processing.

2. High production efficiency.

3. Can make a small section of “口”shape ventilation duct.

4. The minimum section machining can be as small as 200x200mm.

Basic equipments

1. Electric feeding rack 2pcs (3000*1900*950*2)

2. Leveling, beading, punch sharp and square opening die, shearing machine

3. Displacement type joint angle reel bone machine

4. An electric feeding platform

5. Double linkage flange machine

6. A double linkage single bone(angle iron flange machine) machine

7. A servo feeding plate form

8. Hydraulic bending machine

9. A set of computer control system and software production

10. An electrical cabinet

Specifications

| Model | Plate thickness (mm) | Plate width (mm) | Max-working speed (m/min) | Coiler weight (kg) | Weight (kg) | Dimension (mm) |

| SDJL-V | 0.5-1.2 | 1300 | 16 | 6000x2 | 9500 | 18000x3500x1300 |

| 1600 | 10000 | 18000x3800x1300 |

Note: Weight and dimensions not include two feeding rack. Customers can order the line with different sheet specifications, sheet width and coiler weight.

CATEGORIES

LATEST NEWS

CONTACT US

QQ: 2682507192

Phone: 18133429808

Tel: 0555-5207358

Email: oliver.he@tenroy.com

Add: Yanyang road, Huashan district, Maanshan city, Anhui province, China