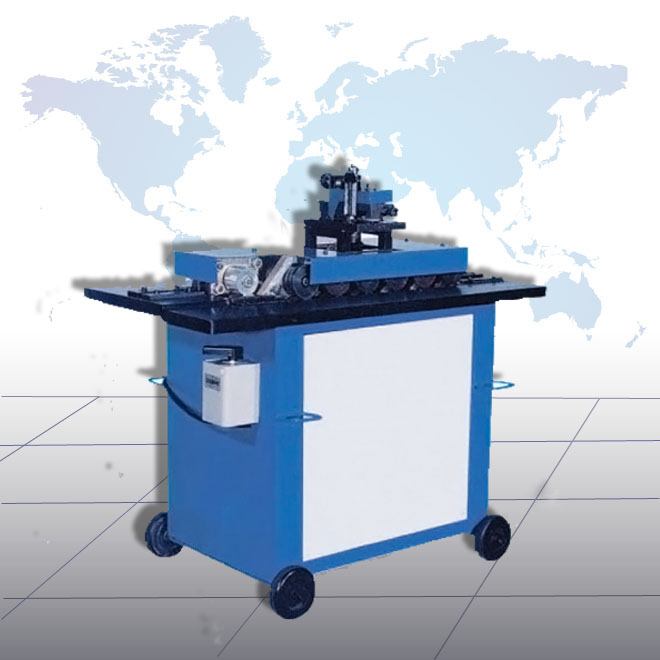

Rectangular Duct Making Machine

Introduction Line IV is linear structure composed by feeding

- Model No.: SA-12HB

- Product Size: 1040*580*820MM

- Net Weight: 230KG

- Product Power: 1.5KW

- Product Material: Galvanized sheet

Lock forming machine is one of the necessary equipment in wind tubes industries. The models are: SA-12, SA-12B, SA-15, SA-15B, SA-15HB etc. Our lock forming machine are easy to operate and convenient to handle. We have a complete range of specifications which can satisfy customer’s need greatly. To equip with our company’s TDF flange machine, five thread grooving machine(leveler grooving machine), TDF folding machine, foot power shearing machine(electric shearing machine) etc, so as to form a simple wind tube production line, and will solve your future problems. It has the features of fast speed, short cycle, high yield and cost saving. And will make your next project in the shortest time.

Lock forming machine is the most widely-used and traditional machinery applied in the manufacture of wind-tubes. Our lock forming machine have been improved based on the traditional products and more customer-oriented, having stepped into the automatic alteration over different functions, which can totally get rid of the trouble in manual change of rollers. The only problem for you is to decide which roller to choose.

The application of this kind machine is: Air duct manufacture in industries of central air conditioning, ventilation duct, muffler, dust project, oil insulation, purification system etc.

Feature

1. All the lock forming machines in our company adopt DEEP GROOVE BALL BEARING instead of the original NEED BEARING to as to ensure the long-term use.

2. Our company’s lock forming machine is one kind of machine with multifunctional of variety change. It can meet different shape requirements in air duct manufacturing.

3. The process thickness is 0.5 to 1.2mm and roller can be changed freely according to customer’s need.

4. All the gears, roller axis uses high quality steel. Through high frequency, carburize, quenching process, it ensure the mechanical durability, stable quality and easy operation which will meet different customer’s requirements.

5. The advantages of our machine is with High quality, easy operation, beautiful appearance, precision structure, flexible movement etc

Specifications:

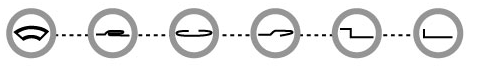

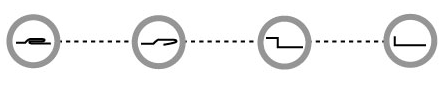

Elbow joint angle lock forming machine

| Model | Power (kw) | Plate thickness (mm) | Weight (kg) | Dimension (mm) |

| SA-12B | 1.5 | 0.5-1.2 | 210 | 1040*580*820 |

| SA-15B | 2.2 | 0.8-1.5 | 230 | 1200*700*1000 |

Multifunction lock forming machine

| Model | Power (kw) | Plate thickness (mm) | Weight (kg) | Dimension (mm) |

| SA-12HB | 1.5 | 0.5-1.2 | 230 | 1040*580*820 |

| SA-15HB | 2.2 | 0.8-1.5 | 250 | 1200*700*1000 |

Joint angle lock forming machine

| Model | Power (kw) | Plate thickness (mm) | Weight (kg) | Dimension (mm) |

| SA-12 | 1.5 | 0.5-1.2 | 195 | 1040*580*820 |

| SA-15 | 2.2 | 0.8-1.5 | 230 | 1200*700*1000 |

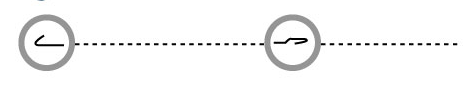

Joint angle insert lock forming machine

| Model | Power (kw) | Plate thickness (mm) | Weight (kg) | Dimension (mm) |

| SA-12H | 1.5 | 0.5-1.2 | 215 | 1040*580*820 |

| SA-15H | 2.2 | 0.8-1.5 | 230 | 1200*700*1000 |

Single lock forming machine

| Model | Power (kw) | Plate thickness (mm) | Weight (kg) | Dimension (mm) |

| SB-12 | 1.5 | 0.5-1.2 | 195 | 1040*580*820 |

| SB-15 | 2.2 | 0.8-1.5 | 220 | 1100*580*1000 |

CATEGORIES

LATEST NEWS

CONTACT US

QQ: 2682507192

Phone: 18133429808

Tel: 0555-5207358

Email: oliver.he@tenroy.com

Add: Yanyang road, Huashan district, Maanshan city, Anhui province, China